For the first time in Morocco and Africa, 2PP 3D-printing was experimentally developed and demonstrated. This milestone represents a significant advancement in photonics and laser-based nanofabrication, highlighting Morocco’s growing capabilities in advanced optical technologies.

By enabling nanoscale 3D structuring with exceptional spatial resolution, 2PP 3D-printing positions the country as an emerging contributor to nanoscale additive manufacturing and optical materials research. The work was carried out by Moroccan researchers affiliated with Mohammed V University and the MAScIR Foundation in Rabat, Morocco, in collaboration with Osaka University, Japan. This international partnership combines local expertise with global research excellence, reinforcing Morocco’s integration into the international photonics research community and underscoring the country’s commitment to advancing high-impact scientific innovation.

Introducing 2PP-Assisted 3D Nanoprinting

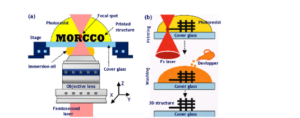

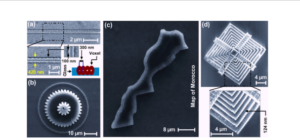

2PP is a next-generation 3D nanoprinting technology that enables the fabrication of extremely small and intricate structures with exceptional precision. It uses ultrafast laser pulses to solidify photosensitive material only at the exact focal point of the laser, providing full three-dimensional control at the micro- and nanoscale (Fig. 1). This capability allows the creation of complex 3D architectures with feature sizes well below one micrometer, far exceeding the limits of conventional 3D printing. As a result, 2PP 3D-printing opens new possibilities in photonics, biomedical devices, and advanced 3D laser micro/nanofabrication. Its ability to produce structures at such a tiny scale is driving innovations in optics, microfluidics, and tissue engineering, shaping the future of high-precision manufacturing (Fig. 2).

Scientific Contributions from Morocco

The development of 2PP-assisted 3D printing in Morocco has emerged from collaborative research efforts among Moroccan scientists specializing in optics, photonics, laser-matter interactions, and materials science.

A significant milestone was reported in 2019 in the “Journal of Micromechanics and Microengineering” through the article “Systematic λ/21 resolution achieved in nanofabrication by two-photon-absorption induced polymerization” which demonstrated a record-high λ/21 fabrication resolution in polymerized nanofibers, enabling the printing of 3D microscale structures.

This was followed in 2020 by an important publication on the Scientific Reports platform addressing fundamental challenges related to voxel control, resolution optimization, and 3D fabrication efficiency in 2PP 3D-printing systems.

Figure 1. How tiny 3D structures are created using 2PP 3D printing. (a) Optical setup: a short laser pulse is focused through a microscope lens into a liquid light-sensitive material. Wherever the laser hits, the material solidifies, “writing” shapes directly in 3D. (b) Steps of 2PP printing: a liquid developer removes the unexposed material after printing, leaving the final solid 3D structure attached to the glass. (a) reproduced with permission from [4] under the Creative Commons CC BY license.

Figure 2. Schematic overview of applications and material types used in 2PP 3D-printing. 2PP enables precise 3D structuring of diverse materials for microfluidics, optics, biomedicine, electronics, and nanomachines. Reproduced with permission from [4] under a Creative Commons Attribution 3.0 Unported Licence.

Figure 3. Scanning electron microscope (SEM) images of tiny 3D objects created using 2PP 3D-printing. (a) an extremely thin fiber only 420 nanometers wide, formed by carefully overlapping laser points. (b) A tiny 3D gear viewed from above. (c) A microscopic 3D map of the Kingdom of Morocco. (d) A microscopic pyramid built with astonishing precision; about 124 nanometers precision. For comparison, a single human hair is about 100 micrometers thick. (a-d) reproduced with permission from [3] under the Creative Commons CC BY license.

Seven years after the introduction of 2PP 3D laser nanoprinting in Morocco, two Moroccan researchers from Ibn Tofail University and the University of Central Florida (UCF) published comprehensive review on 2PP 3D-printing in 2025.

Titled “”Two-photon polymerization-assisted 3D laser nanoprinting: from fundamentals to modern applications”in the Journal of Materials Chemistry C, highlighting advances in printable materials, laser systems, and emerging applications of 2PP 3D-printing. This RSC review highlights the ability of 2PP technology to fabricate complex 3D microstructures with nanometer-scale precision, surpassing traditional lithography methods. 2PP printing enables innovative micro-devices for applications in optics, electronics, and medicine. Despite its promise, technology faces challenges that require further research to fully exploit its potential. The review also discusses 2PP-printing fundamentals, experimental strategies, functional photoresists, and factors affecting resolution and surface quality.

Why This Innovation Matters for Morocco

The successful adoption of 2PP 3D printing marks a major milestone in Morocco’s scientific and technological development. By enabling the fabrication of highly precise 3D microdevices, this technology opens new opportunities across strategic sectors such as photonics, biomedicine, microelectronics, and renewable energy. In photonics, 2PP printing enables the development of advanced optical components and sensors that can be applied to areas of direct relevance to Morocco, including smart agriculture, environmental monitoring, and water management. In biomedicine and tissue engineering, it offers powerful tools for fabricating microscopic scaffolds and bio-inspired structures, supporting future advances in healthcare and biomedical research. The technology also supports emerging applications in micro-devices, microrobotics, and miniaturized systems, which are key enablers for next-generation manufacturing and automation. Overall, 2PP 3D printing strengthens Morocco’s capacity for cutting-edge research, fosters advanced manufacturing capabilities, and positions the country to contribute to global innovation in high-technology industries.

Future Outlook

With the successful establishment of 2PP capabilities in Morocco, future efforts are expected to focus on broadening its applications across photonics, biomedical engineering, microelectronics, and renewable energy. Continued development will aim to enhance the precision, speed, and versatility of 2PP processes, while fostering international research collaborations to integrate Moroccan teams into global networks of advanced manufacturing and laser-based technologies. Translating laboratory-scale achievements into practical industrial solutions will be a key goal, supporting innovation-driven economic growth and strengthening Morocco’s position in high-tech research. This milestone underscores the emerging role of Moroccan scientists in contributing to the global advancement of nanofabrication and 3D micro- and nanoprinting technologies.

Acknowledgment of Sources and Explanation

All scientific content and figures in this article are reproduced with permission from references [1-4]. References [1-3] report that the 2PP 3D-printing work was supported by the Priority Area Project ‘Next Generation Optical Media Recordable via Nano-photonics’ funded by the Moroccan Ministry of Higher Education and Research.

References

[1] Y., Bougdid, I., Maouli, A., Rahmouni, K., Mochizuki, I., Bennani, M., Halim, and Z., Sekkat “Laser nanofabrication in photoresists by two-photon absorption,” Proc. of SPIE 10740, Molecular Machines, 107400G, (2018).

[2] Y., Bougdid, Maouli, I., A., Rahmouni, K., Mochizuki, Bennani, I., Halim, M., and Sekkat “Systematic λ/21 resolution achieved in nanofabrication by two-photon-absorption induced polymerization,” Journal of Micromechanics and Microengineering 29 , 035018, (2019).

[3] Y., Bougdid and Z. Sekkat. “Voxels optimization in 3D laser nanoprinting,” Scientific Reports 10, 10409, (2020).

[4] I., Boudene, and Y., Bougdid. “Two-photon polymerization-assisted 3D laser nanoprinting: from fundamentals to modern applications,” Journal of Materials Chemistry C 13, 18597-18630, (2025).